At Summit, we are not only a scalable manufacturer but also the best and complete design and engineering center in Asia Pacific to offer the seamless solutions from ideas to product development with delivering operational cost savings, while maintaining the highest quality levels.

Customers will receive clear benefits of reliable execution and flexibility to scale.

We are one of the largest multi-specialist plastic solutions suppliers today in Asia Pacific that reliably partners with automotive OEMs and Tier-1s.

100-850

tonnages

154

1,300-1,800

tonnages

33

2,200-3,500

tonnages

39

Double

Injection

2

Blow Molds

6

Summit develops and manufactures airbags, seatbelts and steering wheels to major OEM and Tier 1 partners.

Our world-class lab has offered testing airbag system deployment in our in-house environment chambers and Lighting for high-speed photography (impact tests, pedestrian protection, passenger protection.)

We also offer an extensive crash tests on both newly developed and series vehicles. These tests involve crashing fully equipped test vehicles and series vehicles.

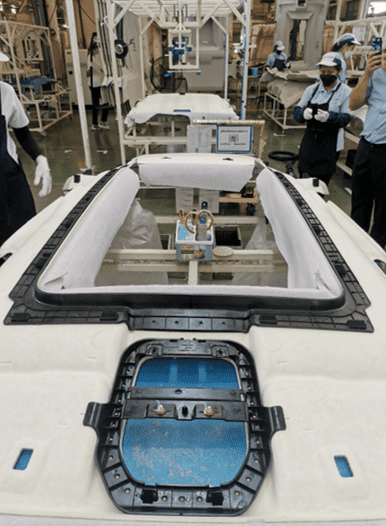

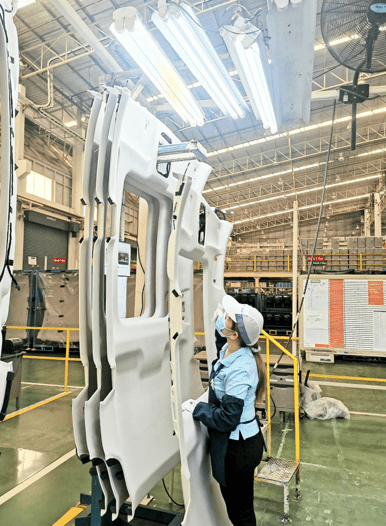

Summit capability covers overhead Interior system- from headliners to grip handles and map lamps.

Summit manufactures a complete overhead interior system for a wide range of customers. Our company provides a full design and development of complete headliner systems for key global automotive brands.

Summit offers a premium technology for automotive carpets that not only scores with its aesthetic appearance, but also has an exceptional environmental performance.

We can source and mold any grade of material from typical commodity grade plastics, to engineering, functional, and structural grade materials in a variety of colors and formulations.

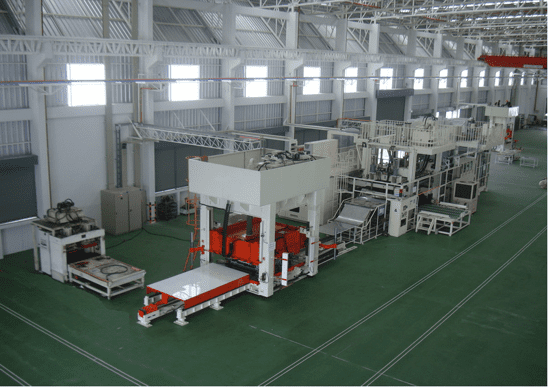

Summit offers custom plastic thermoforming of sizable parts of hood,

dash , fender and various parts of many industries. Our automated equipment allows us to offer high speed, high throughput, and manufacturing of parts. We offer continuous, in-line, cut-sheet, pressure, and vacuum forming.

Summit engineers consider a multitude of factors when designing each system so that the final product meets or exceeds expectations.

New State-Of-The-Art

Automatic Paint Shop

at Indonesia Factory

The Summit Seoyon factory in Bekasi, Indonesia is going to become more flexible and sustainable than ever before with the addition of a new state-of-the-art paint shop. The plant starts its operation in 2022.

This paint shop is the biggest investment made by Summit in decades.

The new paint shop will allow us to make sure of tried and tested technologies.

In the new painting process, a base and surface coat of the grey paint is sprayed in a separate paining to painting chamber.

The functional properties of the coating are improved by the vaporization carried out in between coats of paint.

The new paint shop will not only make the Summit factory more flexible and enable to manufacture of larger machines – and more machines –than before.

The paint shop will further improve the factory’s energy efficiency and safety, including fire safety.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |