Being your partner from design to reality……………….

Global Standard for Acoustic absorption measurement

Our center is one of the top facility in Thailand to test and measure torque and the rotational speed of a machine. Measured data can determine the brake power, speed and other parameters of the rotating machine or an engine.

The intent is to confirm performance before the engine is installed. Power Test dynamometers can help facilities troubleshoot by determining an engine’s functionality while under load.

Additionally, we can verify the quality of a build, rebuild, or repair in a controlled environment before the engine is put into use. Our system is capable of testing engines ranging from 50 to 10,000 horsepower.

The Alpha Cabin has been especially designed for the measurement of acoustic absorption properties of materials and components used for the noise insulation of vehicles.

Summit invests substantially to develop a testing equipment and system for enhanced sound packages and new materials and components for various types of vehicles.

The system recognized throughout the industry that is used by both vehicle manufacturers and suppliers.

Measurement results enable specifications for the absorption properties of NVH products (noise, vibration, harshness) to be drawn up

Fast and easy measurement procedure by a user-friendly software

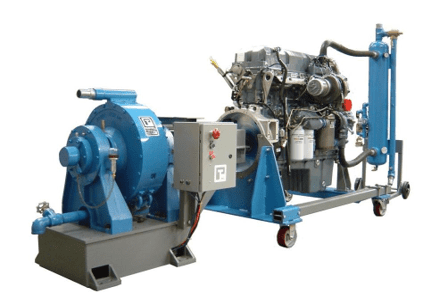

Global Standard for ENGINE MEASUREMENT

Our center is one of the top facility in Thailand to test and measure torque and the rotational speed of a machine. Measured data can determine the brake power, speed and other parameters of the rotating machine or an engine.

The intent is to confirm performance before the engine is installed. Power Test dynamometers can help facilities troubleshoot by determining an engine’s functionality while under load.

Additionally, we can verify the quality of a build, rebuild, or repair in a controlled environment before the engine is put into use. Our system is capable of testing engines ranging from 50 to 10,000 horsepower.

SAVE LIVES IS OUR RESPONSIBILITY

Our airbag static deployment room is one of the important investment as airbags have saved hundreds of thousands of lives.

Optimized airbag deployment protects occupants from airbag impact injuries by adjusting the level and force of inflation based on position and size.

Summit’s 4D imaging radar hardware-software platform gathers rich point cloud data, supporting unique multifunctionality on a single-chip platform.

OEMs and Tier 1s can seamlessly develop and deploy numerous in-cabin monitoring applications with just one sensor, including advanced airbag deployment:

COMPLETE DESIGN AND ENGINEERING PROCESSES

All of our automotive interior trim production tooling is built in-house, thus eliminating wasted time and costs associated with engineering changes.

Speed is everything. Whether you need parts in less than 24 hours or in one week, Summit has the in-house resources to meet your deadline. Depending on your need, we can produce tooling from wood, epoxy, aluminum, and steel to produce parts for appearance evaluation or physical testing.

To ensure that the material properties, tensile strength, push/pull, load, thickness, and all other specifications of your custom plastic injection molding are met; we conducts stringent testing before (PPAP – pre production approval process) and during the molding process based on your part design and requirements.

Our testing processes involves Material Property and Thickness Analysis, Tensile, Push/Pull, and Load Testing, and the use of Spectrometers to ensure your parts optimum performance regardless of final application.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |